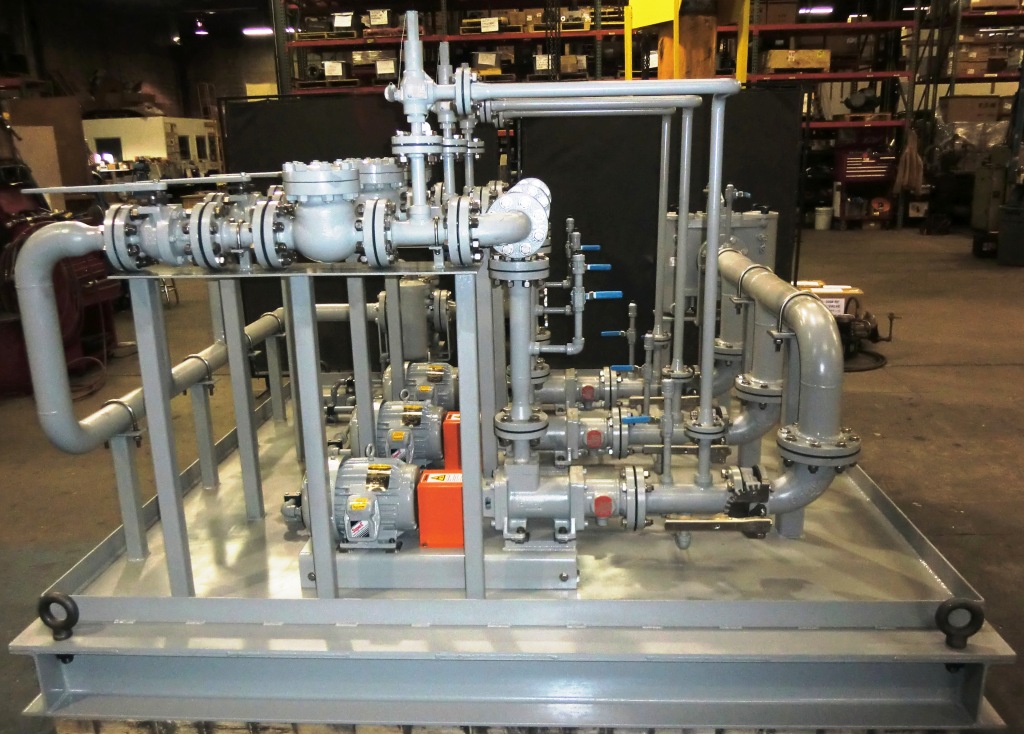

Fuel Oil Pump Sets manufactured and offered by Hayes Pump are designed, engineered and built to deliver best-in-class product that is robust, reliable, and user-friendly. They are constructed and built using first class components, and are backed with Hayes commitment to excellence and support-after-sale.

Fuel Oil Pump Sets Feature:

- Industry leader Viking Pump positive displacement pumps.

- Eaton Duplex Strainers

- Schedule 80 interconnecting threaded piping with union break points and forged steel high pressure threaded fittings.

- Welded-construction main base frame, with 3” Drip Lip and drain connections.

- NEMA 12 Control Panel directly mounted on main base frame.

- Fuel Oil Sets are completely assembled, wired and tested before shipment.

- Complete documentation and operating instruction package is included with each fuel oil set.

- Can be modified, redesigned and built to accommodate customer’s specific requirements, including but not limited to mechanical and electrical modifications.

Here are some examples of Fuel Oil Pump Sets that we have recently built. Their applications are numerous, their versatility unmatched.

Oil Fuel Pump Sets Guidelines

Viking Pump provides these guidelines about Fuel Oil Pump Sets for your information. Pump configurations will vary from application to application. For example, pump options may include relief valves, mechanical seals, steel-fitted construction, carbon bushings, and jacketing to name a few. Drives may vary as well, from direct drives to gear reducers or V-belts.

Slower speeds, lower pressures, and materials designed for the anticipated temperature will pay off in longer trouble-free service, even if oil properties vary from those originally anticipated. Simple do’s and don’ts of oil fuel pumping include:

- Install the pump as close as possible to the supply tank.

- Leave working space around the pumping unit.

- Use large, short, and straight suction piping. “Short and fat” pipes are excellent.

- Install a strainer in the suction line.

- Double-check alignment after the unit is mounted and the piping is hooked up.

- Provide overpressure protection for the discharge side of the pump, either in-line or on the pump.

- Extend service life with preventive maintenance procedures such as periodic lubrication, adjustment of end clearance, and examination of internal parts.

- Obtain, read, and keep the maintenance instructions furnished with your pump.

Don’ts

- Run a pump at faster than approved speeds.

- Run a pump at higher than approved pressures.

- Run a pump at temperatures at higher than approved temperatures.

- Use extra large, extra long suction line with a suction lift.

Installing a vacuum gauge and a pressure gauge on or near the pump will also help lengthen service life. Gauges provide a window into what is happening inside the pumping system. Properly interpreted readings can give clues to the nature of many problems. Long-term readings will show gradual changes taking place within the system.

Given the availability of certain fuels at any particular time, many fuel oil systems now accommodate No. 2 through No. 6 fuel oils. Each fuel oil differs slightly in properties and these differences place unique demands on the system.

For information and quotes on Fuel Oil Pump Sets, please contact us.